High Fiber Composting: Composting Without a Yard or Garden Waste

In simplest terms, high fiber composting involves the combining of fruit and vegetable peelings with shredded cardboard and paper in a container like a bucket or a box. Nature then takes over utilizing the carbon and nitrogen in these materials to trigger the decomposition process, providing you with finished compost (humus).

If you live in an apartment or have limited or no access to yard space, but still want to make your own compost for your house plants, then high-fiber composting could be the answer.

High-fiber composting is a method of composting that doesn’t require any garden waste that can be done indoors or out. It was originally developed by the Centre for Alternative Technology in Wales (UK), to help encourage greater composting of cardboard and paper products, and relieve the pressure on landfill disposal.

How Does High Fiber Composting Work?

The core element of any composting process is the chemical reaction produced by the mixing of carbon and nitrogen in organic materials. The reaction causes a change in temperature resulting in the breakdown of the material through the creation of microbes, converting it into nutrient-rich humus (finished compost).

The ratio between carbon and nitrogen, together with oxygen and moisture, is one of the key factors in the speed with which the material breaks down. The lower the carbon-to-nitrogen ratio the faster the material can decompose. With traditional composting, carbon-to-nitrogen ratios would ideally be around 25 to 30:1 for hot composting. For cold composting, they would be 35:1, or slightly more, and above this for most forms of passive composting.

Cardboard and paper have high carbon-to-nitrogen ratios, 350:1 and 175:1 (C/N) respectively, and are classed as brown organic materials. If mixed with green materials, such as vegetable and fruit scraps, egg shells, and coffee grounds, to name but a few non-garden waste green materials, which have much lower carbon-to-nitrogen ratios.

By combining the cardboard, paper, and correct kitchen waste in the right quantities you can create a batch of material that will have an average ratio of between 25 to 50:1 C/N, right within a range where decomposition can be most efficient.

How to High Fiber Compost

Setting up a high-fiber composting process is very easy. It is merely a matter of collecting and preparing the paper, cardboard, and kitchen scraps.

Container

Ideally, you would want a robust container for the material to compost down in. This could be as simple as a plastic storage box with a lid, a bucket with a lid, or even a robust cardboard box would do. Although if using a cardboard box it might decompose, if you have prepared your material for composting correctly, it will have become finished compost before the boxes start to be attacked.

Drill several ventilation holes in the sides around three-quarters of the way up from the bottom to allow for air circulation.

Preparation of The Materials for Composting

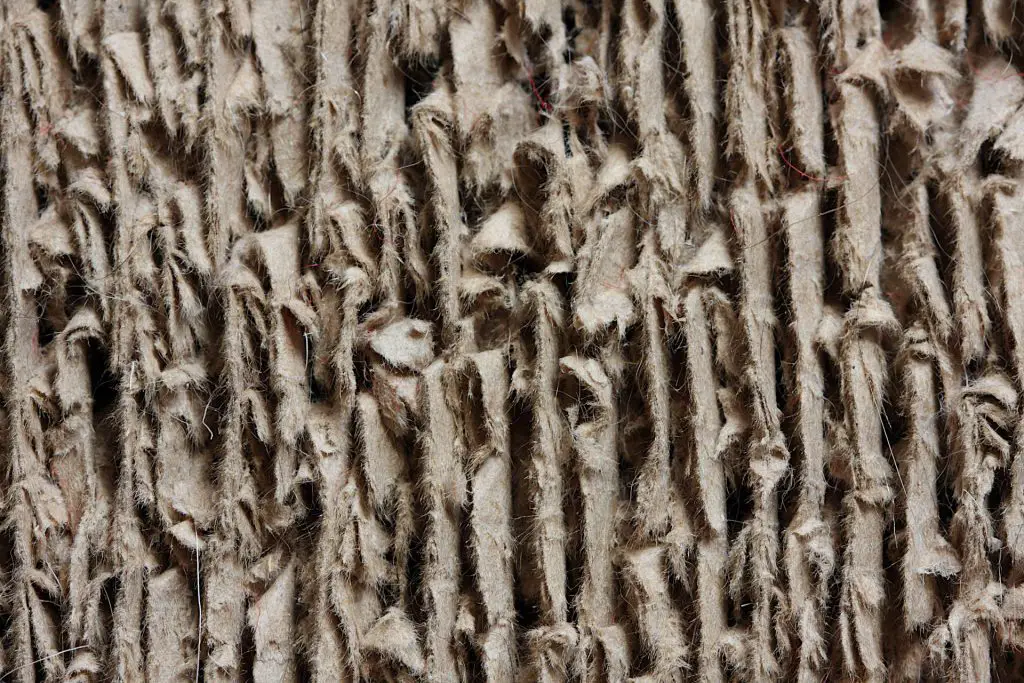

This is an important step. You only need to use cardboard, paper, and kitchen scraps for composting material. The cardboard and the paper will need to be shredded but this can be easily done with a simple paper shredder or other shredding options.

You should probably look to use a carbon-to-nitrogen ratio of around 35 to 40:1 Because cardboard in particular has such a high carbon content the majority of the material will need to be peelings.

| Material | C: N Ratio |

|---|---|

| Cardboard | 350:1 |

| Paper | 175:1 |

| Vegetable and fruit scraps | 15:1 |

| Coffee grinds | 29:1 |

| Egg Shells | 0[1] |

To get to around a 40:1 ratio you will need a mix by weight of around 75% vegetable scraps and 25% of shredded cardboard/paper. You are probably looking at these figures and thinking that I’m not actually composting that much cardboard or paper, but in volume terms, it is more than you think.

Shredded cardboard and paper will weigh considerably less than the vegetable peelings so on sight, i.e. in terms of volume, it will look more like 75% cardboard and paper whereas, by weight, it will be around 75% vegetable peelings and 25% cardboard and paper

Creating Your Pile

If using a storage box or bucket, first line the bottom of the box with a sheet of cardboard, this will help to soak up any excess moisture that might be in the mix. You are then going to layer the materials like lasagne, on top.

- Add a layer of shredded cardboard about an inch thick,

- Then add a layer of vegetable and fruit peelings on the top half ½ inch to inch thick

- Add another layer of shredded cardboard

- Then another layer of vegetable peelings

- Repeat until you have used up all your material

Aerating the Mix When High Fiber Composting

In addition to the carbon-to-nitrogen ratio, oxygen and moisture are both very important in terms of how quickly your compost will decompose.

Every week or two you should aerate your mix. This is fairly simple to do, just take a small towel and turn over the mix a few times to allow air into it mix oxygenating it. There should be adequate moisture from the peelings but if not you can add a fine mist of water if it appears too dry.

By turning it and aerating the mix you will find the pile will heat up. This is what you want as the warmer the pile the faster the decomposition. However, you need to be careful not to turn it too much or you could see the temperature go to over 100°F. Whilst this will greatly hasten the journey to finished compost, if you are using plastic containers or a box it is probably not such a good idea to get it so hot.

Time It Takes to Produce Humus

If you turn your high-fiber composting mix regularly, every ten to fourteen days, then it will probably take around four months or so for you to get finished compost. The more you turn the faster the process. If you are composting outside this is less of an issue and you can probably get finished compost in around three months or less if you can get the pile’s temperature up to 130°F.

On the other hand, if you were not to turn the compost at all the decomposition process would be dramatically slowed down and you could be looking at nine to twelve months to see finished compost

High Fiber Vermicomposting

Another option is to use vermicomposting (composting with worms) for the main decomposition process. You would effectively set up the compost mix in a similar way (see below) but in addition, you would add worms into the mix.

In this scenario, compost ratios are not so important. This means you can compost larger amounts of cardboard and paper, with the worms easily being able to eat through the high-fiber materials. The waste product produced by the worms is known as worm castings, which is high in nutrient values, creating the finished compost.

The Worms

There are specialist compost worms, red wiggler worms (Eisenia fetida) are especially good, and they can be easily got hold of from tackle shops or worm farms. You will need around 1lb per sq Ft (about 800-100 worms).

Preparation of The Materials and Creating Your Pile

The preparation of the materials is the same. The paper or card needs to be shredded and the peelings cut up into small pieces.

Get a container like a bucket or storage box except this time put the aeration holes into the bottom. The container should be dark (worms require a dark environment) so see-through storage boxes are not a good choice.

- Start with a sheet of card to the bottom of the container to soak up excess moisture

- The first layer should be a layer of coffee grounds. Worms particularly like them and are attracted to them

- Next, add a layer of shredded cardboard about an inch thick,

- Then add a layer of vegetable and fruit peelings on the top half a ½ inch to inch thick

- Add in the worms

- Add another layer of shredded cardboard

- Then another layer of vegetable peelings

- Repeat until you have used up all your material

- Finally, add a worm blanket, either a sheet of cardboard or an old t-shirt will do.

Aerating the Mix High Fiber Vermicomposting Mix

You should turn the mix every ten to fourteen days as this will help speed up the process. This is because the worms require oxygen, which they breathe through their skin, creating carbon dioxide, without which they would die.

Time It Takes to Produce Humus with the High Fiber Vermicomposting Process

Using vermicomposting for your high-fiber mix should produce much faster results than composting without worms. Usually, it will take around three months to produce the finished compost.

Scale

We have talked about high-fiber composting in terms of something you can do in your kitchen. This doesn’t mean that you can’t do it outside. On the contrary, it is also well suited to external composting or even using a compost tumbler.

Advantages of High Fiber Composting

The main advantage is that you don’t need to use garden waste so this form of composting is perfect for those that don’t have a garden or yard to collect organic debris. In many respects, it is also much cleaner than when using organic garden waste.

Suitable for Indoor Composting

High-fiber composting is also extremely suitable for indoor composting and is one way of composting over the winter months. The compost box/bin just needs to be stored in a cool dry place. There should also be little or no smell if you have got your carbon-to-nitrogen ratios right and the mix is not too wet.

Eliminating Weed Spores and Pathogens

One advantage of high-fiber composting that is often overlooked is that by not using organic garden waste you eliminate the chance of there being any pathogens or weeds spores in the finished compost, if composting inside or in an enclosed environment.

The result is the finished compost can be more easily used with indoor plants than other types of compost that would need sterilizing first.

Summary: High Fiber Composting

In many ways, the high-fiber composting method is just an extension of traditional composting but replacing all organic garden brown material with cardboard and paper.

The advantages of this are the fact that the process is somewhat cleaner, can be easily carried out indoors, and can eliminate the chances of weed spores and pathogens being present.

The only real disadvantage is that the high carbon-to-nitrogen ratio, particularly cardboard, means a lot more kitchen scraps would be needed to get the overall ratio right. This disadvantage can, however, be mitigated if you were to use a vermicomposting process.

Notes:

- “Egg shells do not contribute either nitrogen or carbon, but will decompose.” – University of Nebraska–Lincoln: Composting Materials: https://extensionpublications.unl.edu/assets/html/g2222/build/g2222.htm