What Is a Hydroseeder? | What Equipment Do You Need for Hydroseeding?

If you are thinking of buying a hydroseeder and getting into hydroseeding as a business, or you are just looking to rent a machine to hydroseed your own lawn, you will need to know how the different types of machines that are available on the market work, in order to assess which is the correct choice for your needs.

If you are serious about the hydroseeding business, there is other machinery and equipment besides a hydroseeder that you will need if you are looking to offer a professional hydroseeding service. Primarily, you are likely to need good ground preparation equipment. The requirements for this equipment, like that for the hydroseeder, can vary widely and depend largely on the size and scale of projects you are looking to undertake.

In this article, we will take an in-depth look at what is going to be the right equipment for various different scenarios. This should help and guide you in making an informed decision about what preparation equipment and which type of hydroseeder is best for your needs.

What Equipment Do You Need for Hydroseeding?

The initial starting point is to consider the basic equipment that you are going to need for hydroseeding. Clearly, you are going to need a hydroseeder, and there are numerous options that are available which we will look at in more detail below, but first, we will look at other equipment that you are going to need that you might not yet have considered.

Ground Preparation Equipment

Although the hydroseeder is going to be your key piece of equipment. The success or failure of a project can all depend on preparation. Depending on what you intend, your standard operating procedure should include site preparation.

Although, in some instances, you may be able to get away with little or no preparation at all and simply apply the material directly to the ground, to get the best results, you are going to need good ground preparation of the area that you are going to be working on.

Ground preparation usually entails clearing out weeds, removing stones and other debris from the surface, rototilling the surface, and making sure that you have enough water in order for the seed to have the best conditions in which to thrive in once put down in the slurry. You should therefore ensure that you have the right and adequate tools for the job.

Of course, the type of equipment you need will depend on the scale of the hydroseeding jobs that you undertake. In terms of ground preparation for residential lawns, you are going to need to look at rototilling equipment for bare ground and possibly aerators, scarifiers, and dethatchers for hydroseeding over existing lawns.

If you are looking at larger areas (more than three or four acres), then you might have to consider tractors and disc harrows or other suitable attachments. In between residential-size lawns and large commercial areas, you might find that a Skid Steer Power Rake might suffice for grading soil and gravel, preparing seedbeds, and removing rubbish. These types of power rake have greater torque than chain-driven alternatives and generally need less upkeep.

Which Type of Hydroseeder Do You Need?

If you have the ground preparation equipment nailed down, then the next consideration is the hydroseeder itself. The question of which is the right hydroseeder must first be prefaced with what a hydroseeder actually is. It is surprising that many don’t understand what a hydroseeder can actually do and, therefore, can miss out on other opportunities.

What Is a Hydroseeder?

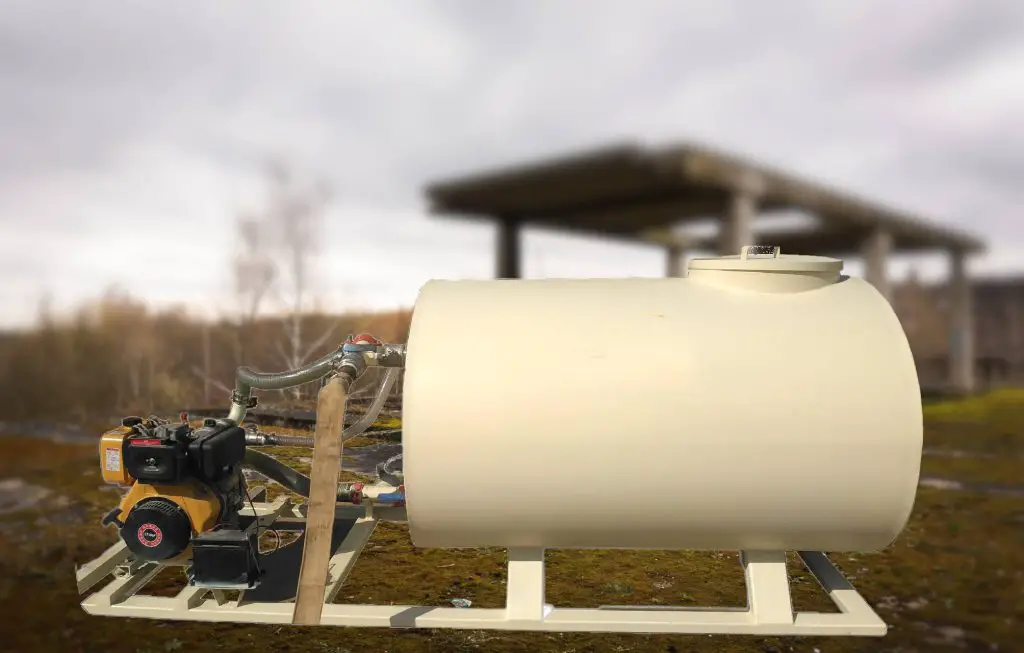

Essentially, a hydroseeder is a machine that blends seed, mulch, fertilizer, and other materials, such as tackifiers, dyes, and bonding polymers, into a slurry and then distributes this mixture, under pressure, through a hose onto the designated area.

You will notice that the words grass or lawn doesn’t appear in the above definition. Whilst it is true that it is the grass is the seed that is predominantly used with hydroseeders, they can, in fact, spray any seed. This can be wheat, barley, wildflowers, or a mixture of various types of seed, all of which are regularly used with hydroseeders.

What Can You Use a Hydroseeder For?

Indeed, a hydroseeder machine can serve many use cases. Because of the way it delivers seed through a hand-held hose or turret cannon, it can be used to distribute seed across difficult terrain. In addition, its mixing process allows it to include a wide range of materials, together with or separate from seed, which makes it ideal for dealing with issues such as soil erosion.

It is best to think of a hydroseeder as a mixer and distribution system through which you can lay down various different seeds and mulches, which all can have very different end goals, from laying a new lawn to soil erosion control.

What Are the Different Types of Hydroseeder?

Whilst hydroseeding machines can be used to spread any type of seed, it is most likely that you looking to use it to seed grass and pasture, and it is in these terms that you will probably want to consider which machine to buy. As hydroseeders are available in different sizes and can have different tank mixing mechanisms, you also need to consider the range of use and allow some flexibility for future expansion of the project scale.

Some use cases require more scale than others, and this will impact the size of the machine that you need to purchase. It is important to bear in mind that industrial applications and erosion control are likely to be larger-scale projects and thus need greater capacity.

Hydroseeder machines come in various different sizes and capacities. In the main, hydroseeders can be categorized by their tank mixing system. There are essentially two types of mixing systems, jet-agitated machines, and paddle-agitated machines. Both types have advantages and disadvantages, but generally, paddle agitated machines are much bigger and can handle bigger projects.

Jet Agitated Hydroseeders

Compared to a paddle agitated machine, a Jet type of machine has far fewer moving parts and therefore tends to need less maintenance. They are also quick and simple to clean up at the end of each day. Because they all usually have plastic tanks, there is no need to be concerned about tank corrosion.

They are smaller in size, sometimes useful in terms of difficult site access, and are much lighter in weight. Perhaps their biggest benefit is that they also cost considerably less than the paddle agitated brothers.

In terms of drawbacks, it is usually necessary to split up mulch bales when mixing. Whilst the Jet agitated machines are well suited to most kinds of materials that you would use for hydroseeding residential lawns, they can struggle with specialist materials used in erosion control, such as bonded fiber matrix (BFM) and flexible growth medium (FGM). Some machines, at the cheaper end, can even struggle with wood-fiber mulch.

In reality, Jet agitated machines are best suited for straw, paper cellulose or wood/paper blended mixes that are more commonly used in temperate climates for residential hydroseeding.

Paddle Agitated Hydroseeders

Paddle-agitated hydroseeders are very much the Jet agitated machine’s big brother. Whilst generally being bigger in every way they also have their drawbacks.

The majority of them will be able to handle full mulch bales without the need to break them down, and on the whole, they can handle much heavier mixes than jet-agitated machines. The majority of paddle machines can cope with any substance used in hydroseeding and hydromulching, whether residential or industrial, so they can easily cope with erosion control materials such as the BFMs and FGMs, and other similar products that Jet systems struggle with or can’t.

The downside to a paddle agitated system is that the mechanisms are more complex, which ultimately can lead to higher maintenance costs. This can be as much a daily regime as the shafts and gear pumps need regular oiling. The upshot is that there can be more downtime and much higher maintenance costs than jet agitated systems.

One other thing to note is most paddle agitated machines on the market have metal tanks. This means that you have to pay careful attention to the tanks during cleaning, or you might experience corrosion.

What Kind of Pump Is on A Hydroseeder?

The pumps used in Jet and Paddle agitated systems differ. Pumps for Paddle agitated units tend to be either centrifugal or gear-driven, depending on the application.

A centrifugal pump is a mechanical pump designed to move a slurry through the system through the use of rotors, known as impellers. The mix enters the “impeller chamber” and is pushed out by a centrifugal force that is generated, creating a powerful distribution mechanism for the mulch or slurry.

Both of these pumps work well, and choice can come down to maintenance and the personal preference of the contractor.

Jet machines, on the other hand, are powered by either a slurry pump or a trash pump. A trash pump is a kind of pump that is used for “dewatering” processes. Trash pumps are designed to move and distribute enormous volumes of liquid, which can contain including both hard and soft materials. This means that the slurry mix can be easily distributed through the system.

The commonality between all the types of pumps used is that they are designed to handle liquids and slurry easily, thereby providing an efficient delivery mechanism for the hydroseeder.

What size Hydroseeder do I need?

As we have seen, if you are looking to do small to medium size jobs, then a Jet agitated system is likely to be adequate, especially if you invest in a machine with a 300 to 500-gallon tank size. Good machines this size can actually probably handle projects up to two to three acres in size and some types of slope.

If, on the other hand, you are looking to concentrate on bigger jobs on the industrial side of hydroseeding, such as slopes, road embankments, and erosion control, it is better to look at the paddle agitated system.

How Much Does a Hydroseeder Machine Cost?

There is a huge disparity in price for hydroseeders. As this is written, in the spring of 2023, you can buy a new jet agitated hydroseed for as little as $3,000, although this is a very small machine, with just a 100-gallon tank size, and not suitable for much other than small residential lawns and DIY hydroseeding.

You can, however, get some excellent machines for between $5,000 and $10,000 with 300-gallon tank capacities that could be used with relative ease on residential projects and even some bigger sites. If you have a larger budget, you can pay up to $15,000 or more for a Jet machine. For this, you are getting bigger tanks ( 500 gallons) and better pumps, which will be able to handle smaller industrial projects.

If you are looking at paddle agitated machines, then although you can get smaller models for around $13,000, for an average-size machine, you can pay from $20,000 to north of $100,000 for some of the biggest machines. These are truly very capable hydroseeders, although the size and access to certain sites might be an issue.

Pros and Cons of Jet Agitated Hydroseeder

| Advantages | Disadvantages |

|---|---|

| Visual cue regarding the amount of mixture left in the tank | Cant add full mulch bales without splitting |

| Simple to use | It can usually be operated by one person |

| Jet-agitated hydroseeders are inexpensive | Can’t handle materials like BFM or FGM |

| Can distribute a reasonably thick slurry | |

| Tend not to clog easily | |

| Fewer moving parts, simpler maintenance | |

| Fast machine clean up after use | |

| Fast machine clean-up after use | |

| Smaller, fewer problems with site access |

Pros and Cons of Paddle Agitated Hydroseeder

| Advantages | Disadvantages |

|---|---|

| Easier to load no need to split up mulch bales | Bigger machines can handle industrial projects at a scale |

| Can handle much thicker slurry | Tanks can be subject to corrosion |

| More mechanical parts, higher maintenance | Machines more expensive |

| Machines can pump through longer hoses | Pumps need replacing more often |

| Can have further reach with platform gun | Site access problems with bigger machines |

| Can have bigger capacity tanks | |

| Bigger machines can handle industrial projects at scale |

Final Thoughts

It is important to get the right equipment in place for your target projects. That being said, there is considerable flexibility in your choices. Indeed if you are looking only to get into hydroseeding on a small scale, concentrating on residential lawns, then you could have an excellent setup for under $10,000

In terms of the actual hydroseeder system that you buy, both paddle and Jet systems seem to be popular among those who use them, and you probably can’t go wrong with either one, provided you don’t push their capabilities too far.

Further Reading

- City Of Phoenix: 430.12.3 Hydroseeding Lawn Areas (page 212)

- U.S. Department of Agriculture: After the Fire – Hydromulching